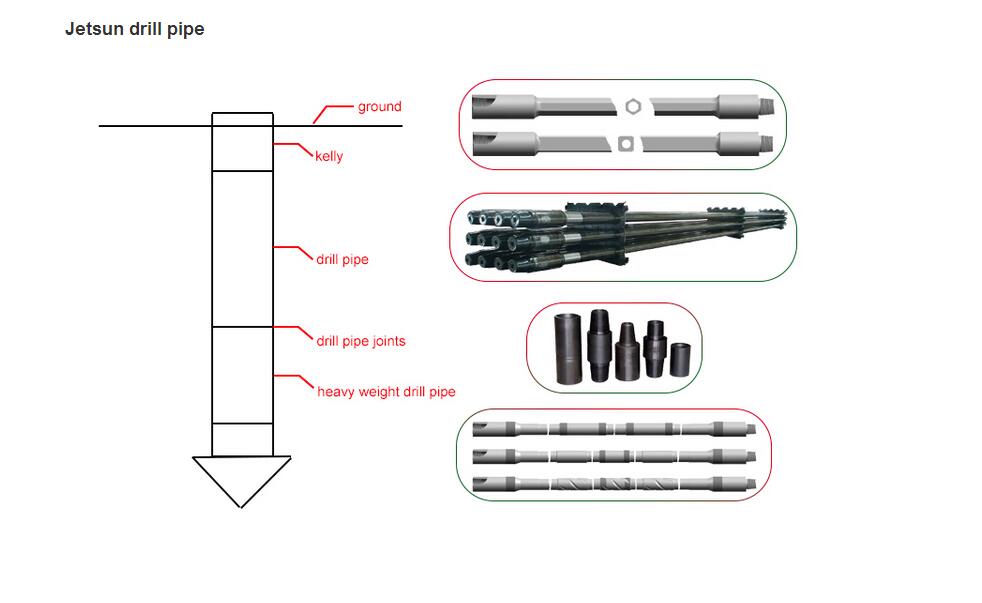

Drill Pipe

Introduction

Specification

Application: Used for oil well drilling, it is mainly used for the drilling process and after completion of borehole wall support, to ensure that the drilling process and the whole Wells after completion are normal runnings.

Applicable hard, very hard and medium soft rock formations.

Reliable quality, long service life, rare abnormal breakage during service life.

Good flushing effect to ensure high drilling rate.

Strict quality warranty and compensation rules.

API 5DP Drill Pipe

Standard:API SPEC 5D

Application:For well drilling

Outer Diameter:2 3/8"~5 1/2",60.3mm~139.7mm

Wall Thickness:0.28"~0.415",7.11mm~10.54mm

Size

| Outer Diameter | Norminal Weight | Calculated Weight | Grade | Wall Thickness | Upset Ends,for Weld-on Tool Joints | Tool Joint Designation | ||||

| In | mm | lb/ft | kg/m | In | mm | |||||

| 2 3/8" | 60.3 | 6.65 | 6.26 | 9.32 | E.X.G.S | 0.28 | 7.11 | EU | NC26 | |

| 2 7/8" | 73 | 10.4 | 9.72 | 14.48 | 0.362 | 9.19 | EU | NC31 | ||

| 3 1/2" | 88.9 | 13.3 | 12.31 | 18.34 | 0.368 | 9.35 | EU | NC38 | ||

| 3 1/2" | 88.9 | 15.5 | 14.63 | 21.79 | 0.449 | 11.4 | EU | NC38,NC40 | ||

| 4" | 101.6 | 14 | 12.93 | 19.26 | 0.33 | 8.38 | IU,EU | NC40 | ||

| 4 1/2" | 114.3 | 16.6 | 14.98 | 22.31 | 0.337 | 8.56 | EU,IEU | NC46,NC50 | ||

| 4 1/2" | 114.3 | 20 | 18.69 | 27.84 | 0.43 | 10.92 | EU | NC50 | ||

| 5" | 127 | 19.5 | 17.93 | 26.71 | 0.362 | 9.19 | IEU | NC50 | ||

| 5" | 127 | 25.6 | 24.03 | 35.79 | 0.5 | 12.7 | IEU | NC50 | ||

| 5 1/2" | 139.7 | 21.9 | 19.81 | 29.51 | 0.361 | 9.17 | IEU | 51/2FH | ||

| 5 1/2" | 139.7 | 24.7 | 22.54 | 22.57 | 0.415 | 10.54 | IEU | 51/2FH | ||

| Note: 1.EU-External Upset,IEU-Internal&External Upset. 2.Threads of tool joint are right-hand or left-hand. 3.Threads are copper-plated phosphorulized. |

||||||||||

Thread Parameter Tolerance

| Thread Parameter Tolerance

|

||||

| Name

|

Taper mm/m

|

Pitch per in. mm

|

Stand off mm

|

|

| 2 7/8"-5" Drill Pipe

|

Pin

|

+2.5

|

±0.038

|

(+0.254 -0.127)

|

| Box

|

-2.5

|

±0.038

|

-0.254

|

|

Chemical Composition

| Chemical Composition | ||

| Grade | Chemical Composition% | |

| P≤ | S≤ | |

| E-75 | 0.015 | 0.003 |

| X-95 | 0.015 | 0.003 |

| G-105 | 0.015 | 0.003 |

| S-135 | 0.015 | 0.003 |

| Tool Joint | 0.015 | 0.003 |

Mechanical Properties

| Mechanical Properties | ||||||||||||

| Pipe Body | Grade | Yield Strength | Tensile Strength | Elongation% | Hardness | Longitudinal charpy impact(J) | ||||||

| min | max | min | min | |||||||||

| Psi | Mpa | Psi | Mpa | Psi | Mpa | HB | HRC | Average | Each | |||

| E-75 | 75000 | 517 | 105000 | 724 | 100000 | 689 | 625000A^0.2/U^0.9 | / | / | 80 | 65 | |

| X-95 | 95000 | 655 | 125000 | 862 | 105000 | 724 | / | / | 80 | 65 | ||

| G-105 | 105000 | 724 | 135000 | 931 | 115000 | 793 | / | / | 80 | 65 | ||

| S-135 | 135000 | 931 | 165000 | 1138 | 145000 | 1000 | / | / | 80 | 65 | ||

| Weld Zone | Tool Joint | 120000 | 827.4 | / | / | 140000 | 965.3 | ≥13% | ≥285 | / | 80 | 65 |

| E-75 | 75000 | 517 | / | / | 100000 | 689 | / | ≤37 | 40 | 27 | ||

| X-95 | 88000 | 609 | / | / | 103000 | 712 | / | ≤37 | 40 | 27 | ||

| G-105 | 95000 | 655 | / | / | 105000 | 724 | / | ≤37 | 40 | 27 | ||

| S-135 | 105000 | 724 | / | / | 115000 | 793 | / | ≤37 | 40 | 27 | ||